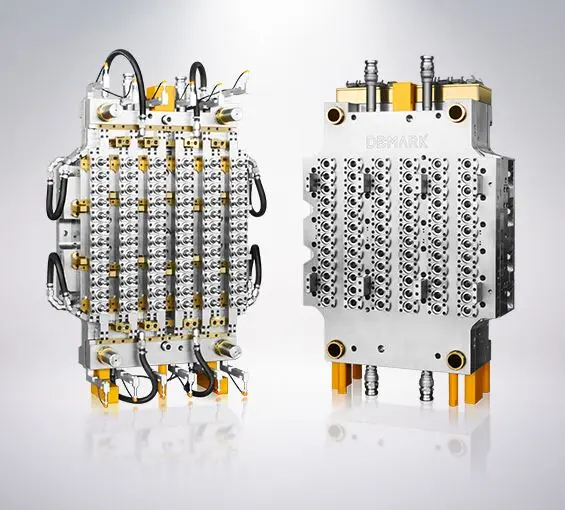

16,24腔高速压盖机

● 16,24,Cavities Cap Compression Machine

● Output: 1200 pcs/cavity/hr

● More than 45% of plastic beverage caps are produced through compression.

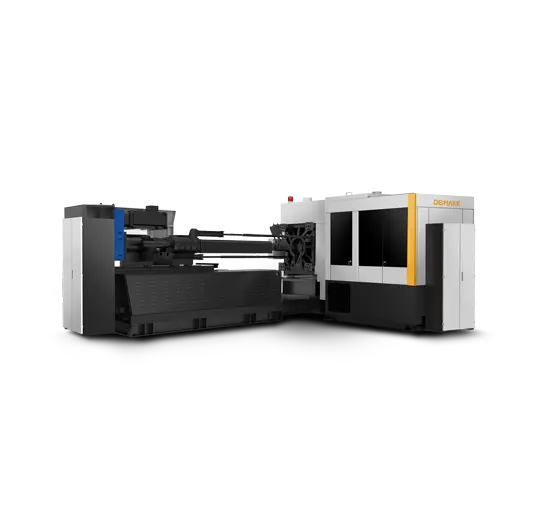

● The DMK-CM plastic cap compression molding machine(continuous compression molding machine),as the innovation of the second generation of plastic cap molding processing, produces all sizes of both CSD and water caps with high efficiency and quality from PP & PE resin. This fully automatic cap compression molding machine is warmly welcome by customers with the advantages of high output, low consumption and labour saving

● The DMK-CM plastic cap compression molding machine, completely controlled by computer, has excellent stability and durability. Caps made by this machine have smooth & nice appearance, no injection point and size conformity, comparing with similar traditional injection machine, the output is increased by 3 times, and the usage of raw materials increased up to 98% with environmental production and no hot runner waste. Meantime, this machine saves human labour a lot, decreaseuse of the floor area and finally save energy. Specialrequests from customers like printing marks and logo can also be realized accordingly with low cost and high efficiency

● DMK-CM hydraulic rotary presses are specially designed to produce thermoplastic products by means of compression. A continuous work cycle is carried out, during which the plastic material is fed by a plasticization unit, cut into suitably sized pellets and then inserted inside the cavities. More than 45% of plastic beverage caps are produced through compression.

● The DMK-CM plastic cap compression molding machine, completely controlled by computer, has excellent stability and durability. Caps made by this machine have smooth & nice appearance, no injection point and size conformity, comparing with similar traditional injection machine, the output is increased by 3 times, and the usage of raw materials increased up to 98% with environmental production and no hot runner waste. Meantime, this machine saves human labour a lot, decreaseuse of the floor area and finally save energy. Specialrequests from customers like printing marks and logo can also be realized accordingly with low cost and high efficiency

● DMK-CM hydraulic rotary presses are specially designed to produce thermoplastic products by means of compression. A continuous work cycle is carried out, during which the plastic material is fed by a plasticization unit, cut into suitably sized pellets and then inserted inside the cavities. More than 45% of plastic beverage caps are produced through compression.

| ITEMS | UNIT | DMK-CM16 | DMK-CM24 | DMK-CM36 |

| Raw material | PP/HDPE/LDPE/PTE | PP/HDPE/LDPE/PTE | PP/HDPE/LDPE/PTE | |

| Max capacity | PCS/hr | 13000 | 25000 | 32000 |

| Diameter of cap | mm | 22-45 | 22-45 | 22-45 |

| Height of cap | mm | 10-25 | 10-25 | 10-25 |

| Number of cavity | PCS | 16 | 24 | 36 |

| Actual power consumption | KW | 16-20 | 25-28 | 32-35 |

| Operating pressure | MPA | 0.8 | 0.8 | 0.8 |

| Pressure consuming | M3/hr | 1.0 | 1.0 | 1.0 |

| Power supply | V/HZ | 380v 50hz | 380v 50hz | 380v 50hz |

| Machine weight | TON | 3.8 | 5 | 7.5 |

| Dimension | mm | 3800*1750*2650 | 4300*1950*2650 | 5900*2180*2600 |

| Installation power | KW | 40 | 55 | 75 |

| ITEMS | UNIT | DMK-CM16 | DMK-CM24 | DMK-CM36 |

| Raw material | PP/HDPE/LDPE/PTE | PP/HDPE/LDPE/PTE | PP/HDPE/LDPE/PTE | |

| Max capacity | PCS/hr | 13000 | 25000 | 32000 |

| Diameter of cap | mm | 22-45 | 22-45 | 22-45 |

| Height of cap | mm | 10-25 | 10-25 | 10-25 |

| Number of cavity | PCS | 16 | 24 | 36 |

| Actual power consumption | KW | 16-20 | 25-28 | 32-35 |

| Operating pressure | MPA | 0.8 | 0.8 | 0.8 |

| Pressure consuming | M3/hr | 1.0 | 1.0 | 1.0 |

| Power supply | V/HZ | 380v 50hz | 380v 50hz | 380v 50hz |

| Machine weight | TON | 3.8 | 5 | 7.5 |

| Dimension | mm | 3800*1750*2650 | 4300*1950*2650 | 5900*2180*2600 |

| Installation power | KW | 40 | 55 | 75 |

* 德玛克保留对产品进行更改的权利,如有更改,恕不另行通知。